Students design a $300 ventilator for the pandemic’s medical equipment shortage - Yanko Design

As we all do our part in fighting the coronavirus pandemic, our health professionals are working round the clock without the required protective gear or medical equipment to safeguard themselves and keep saving lives. Without these essentials, they are at high risk of catching the virus and the lack of resources can bear upon the lives that tin can be saved. The global community is pitching in to assistance in every fashion they can – start-ups printed 3D valves and turned scuba diving masks into ventilators (if y'all have a printer to spare, the blueprint file is bachelor for download), designers at MIT making makeshift ICU pods and way brands producing PPE (personal protective gear) for healthcare professionals. Joining this forcefulness is Rice University's Oshman Engineering Design Kitchen (ODEK) who has managed to develop a low-price ventilator with the assistance of Metric Technologies, named the ApolloBVM.

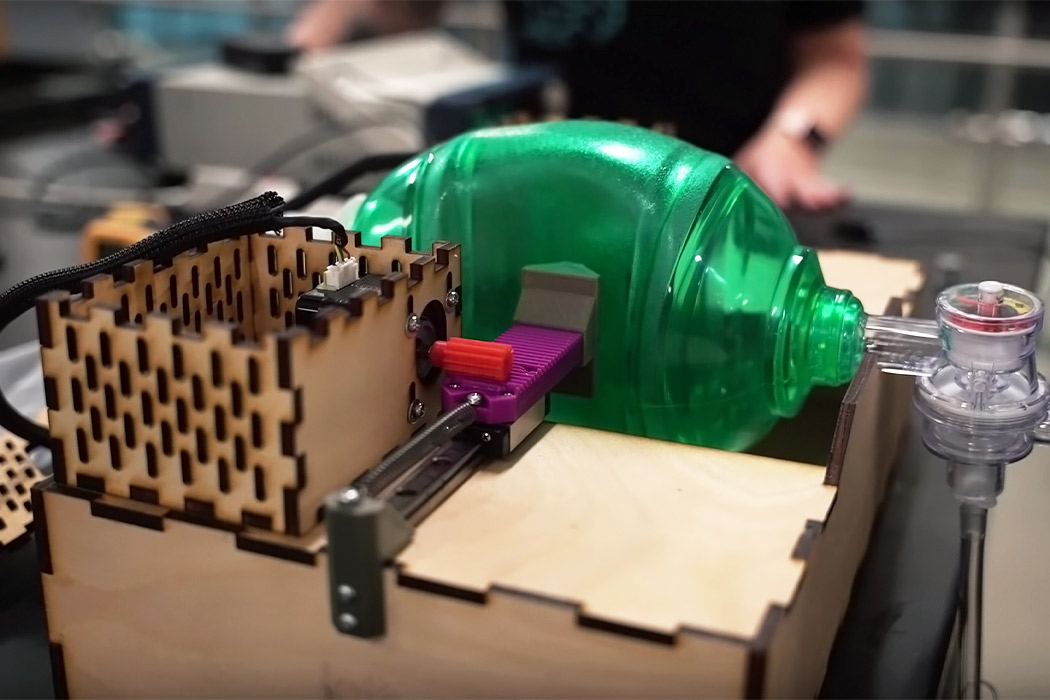

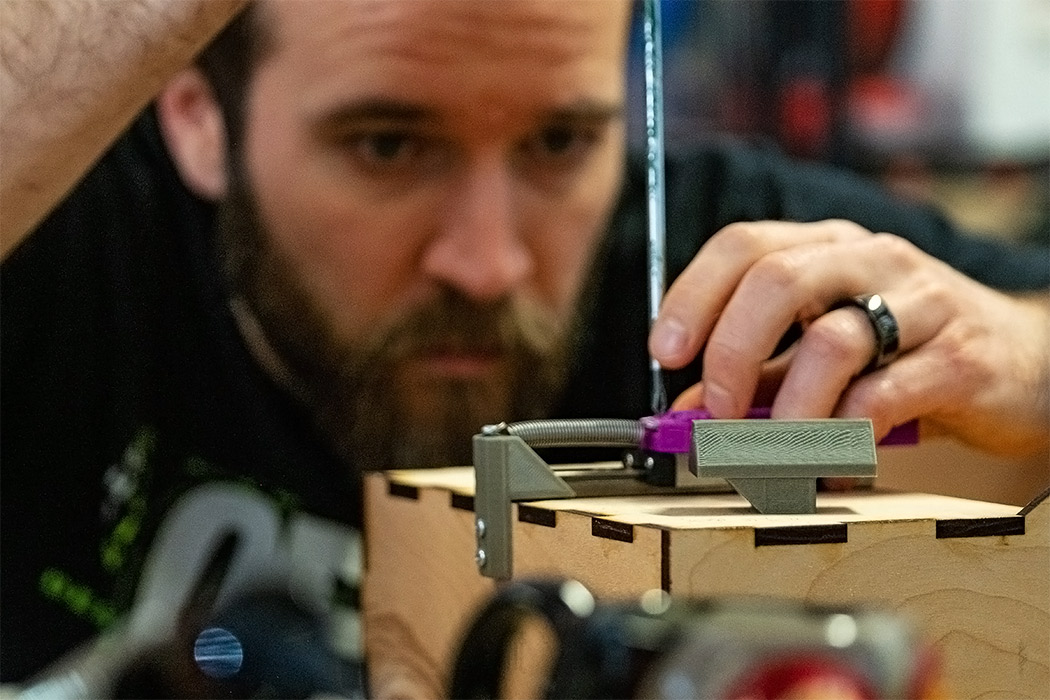

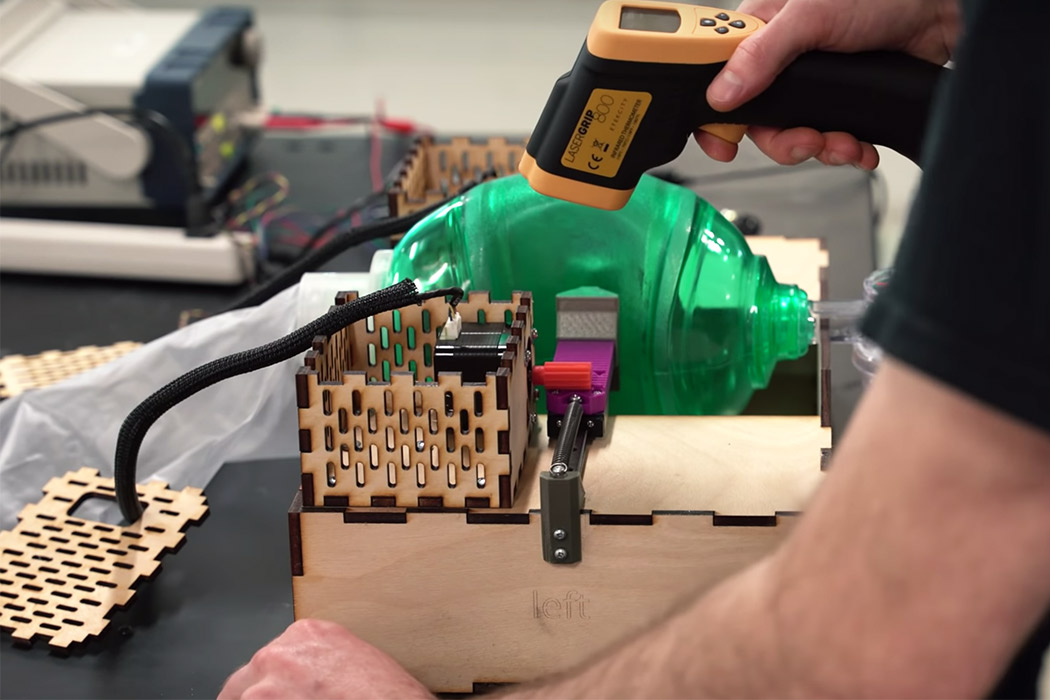

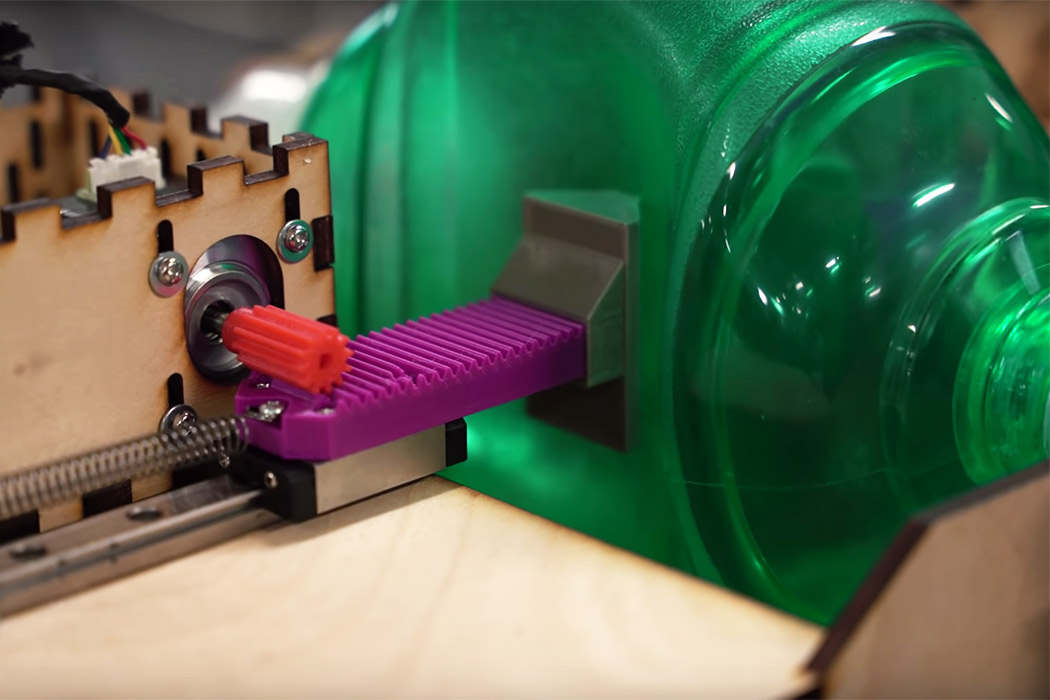

In that location is a worldwide shortage of medical equipment, especially ventilators as traditionally they are expensive and fourth dimension-consuming to produce at the rate this virus is moving. ODEK'due south culling costs less than USD 300 and information technology works on an automated mechanism that squeezes the common bag valve mask ventilation devices that are available in hospitals. This device is ordinarily chosen an Ambu bag and the ApolloBVM tin can save the hours that healthcare professionals spend on manually pumping bags when in that location are no ventilators bachelor. An wearied human cannot pump air for extended periods of time with the precision of a machine, and so with this device, information technology will exist a lot easier to assist patients that need aid to exhale. The device will as well include feedback sensors that assist fine-melody the flow of air to the lungs, as well as motors like to those that power 3D printers for hours on finish.

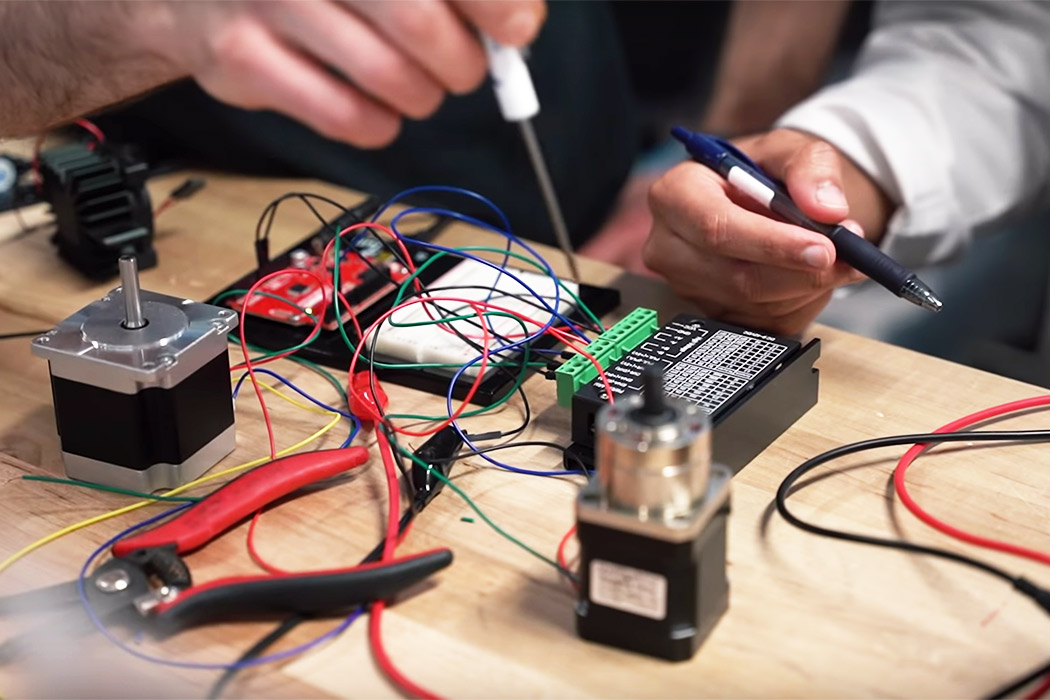

"The prototype device uses an Arduino board to facilitate programming that allows the adjustment of the rate at which the pocketbook is squeezed," says the team who is working on creating a custom integration excursion to replace the Arduino board that volition further reduce the cost of the device. This volition assistance in keeping non-critical patients stable and free upward resources for those more in need of them. The students had created a program for this in 2022 and they called it 'Have A Sabbatical' unaware of the fact that in a few months their epitome could help save lives. The squad wants to brand the production plan public and then anyone in the world can take access to it and join the effort in coping with the crisis, one of them said it was for all of humanity and we couldn't thank these immature globe-changers enough.

Designer: ODEK (Rice University), Dr. Matthew Wettergreen, Dr. Rohith Malya, and Metric Technologies

mixonvadvapegul1994.blogspot.com

Source: https://www.yankodesign.com/2020/04/01/students-design-a-300-ventilator-for-the-pandemics-medical-equipment-shortage/

0 Response to "Students design a $300 ventilator for the pandemic’s medical equipment shortage - Yanko Design"

Post a Comment